The Future of AI and Robotics in Workplace Safety

What You Really Need to Know

How AI and Robotics Are Changing Workplace Safety

AI and robotics in workplace safety are rapidly transforming how Irish organisations identify hazards, manage risk, and protect workers. Advances in artificial intelligence, robotics, and automation are enabling businesses to move from reactive incident response to proactive, data-driven risk prevention that aligns with modern HSA expectations.

The integration of artificial intelligence and robotics into workplace safety management represents one of the most significant technological shifts facing Irish businesses today. What was once the realm of science fiction is rapidly becoming practical reality, with AI-powered systems already transforming how organisations identify hazards, predict risks, and protect workers across industries from construction to healthcare. For Irish safety professionals, understanding and harnessing these emerging technologies offers unprecedented opportunities to move from reactive incident response toward genuinely proactive risk prevention.

Current adoption patterns in Irish workplaces reveal a mixed landscape, with forward-thinking organisations beginning to implement AI-driven safety solutions whilst others remain cautious about embracing technologies that fundamentally change traditional approaches to risk management. Early adopters are discovering that AI and robotics don’t replace human expertise they amplify it, providing safety professionals with powerful tools for pattern recognition, predictive analysis, and automated monitoring that human capabilities alone cannot match.

TRANSFORMATION ACCELERATION: Research indicates that AI-powered safety systems can reduce workplace incidents by 20-35% through predictive analytics and real-time hazard detection. Early adopters report 40-60% improvements in safety audit efficiency, whilst automated monitoring systems provide 24/7 oversight capabilities that would require substantial human resources to achieve manually.

This technological revolution matters now because workplace safety challenges are becoming increasingly complex whilst regulatory expectations continue to evolve. The HSA’s emphasis on systematic safety management aligns naturally with AI capabilities for data analysis, pattern recognition, and continuous improvement. Irish businesses that understand and strategically implement these technologies position themselves for competitive advantages that extend far beyond compliance requirements.

AI-Driven Predictive Analytics From Reactive to Proactive

Predictive analytics represents perhaps the most transformative application of AI in workplace safety, fundamentally shifting focus from responding to incidents after they occur toward identifying and preventing risks before they materialise. AI systems analyse vast quantities of historical incident data, safety observations, environmental conditions, and operational metrics to identify patterns that human analysis might miss or take significantly longer to recognise.

Pattern recognition across multiple data sources enables AI to correlate seemingly unrelated factors that contribute to increased risk. For example, AI might identify relationships between weather conditions, shift patterns, equipment maintenance schedules, and incident rates that reveal previously unknown risk multipliers. These insights enable safety managers to implement targeted interventions during high-risk periods rather than applying uniform precautions regardless of actual risk levels.

Real-time risk scoring provides dynamic assessment capabilities that adjust continuously based on current conditions, workforce factors, and operational parameters. In construction contexts, AI systems can analyse project scheduling data, weather forecasts, worker experience levels, and equipment status to generate daily or even hourly risk assessments that inform resource allocation and safety intervention decisions. Machine learning algorithms continuously improve their accuracy by learning from new data inputs and validation against actual outcomes.

Integration with Existing Safety Systems

Successful AI implementation requires seamless integration with existing safety management systems rather than wholesale replacement of established procedures. Modern AI platforms can incorporate data from incident management systems, training records, inspection reports, and environmental monitoring equipment to create comprehensive risk profiles that inform decision-making across all levels of the organisation.

Practical applications demonstrate AI’s value in construction scheduling optimisation that considers safety risks alongside productivity targets, predictive maintenance programmes that prevent equipment failures before they create hazardous conditions, and workforce allocation strategies that account for individual competency levels and cumulative fatigue factors.

Integration with Existing Safety Systems

Computer vision technology enables AI systems to “see” and interpret workplace environments in real-time, providing continuous monitoring capabilities that detect hazards and unsafe behaviours as they occur. These systems use advanced image processing algorithms to identify objects, people, and activities within camera feeds, comparing observed conditions against safety standards and alerting supervisors to potential problems immediately.

PPE compliance detection represents one of the most mature applications of computer vision in workplace safety. AI systems can automatically verify that workers are wearing appropriate hard hats, safety glasses, high-visibility clothing, and other required protective equipment before entering hazardous areas. When non-compliance is detected, systems can trigger immediate alerts to supervisors whilst preventing access to restricted areas through integrated access control systems.

Dangerous proximity alerts provide real-time warnings when workers approach hazardous machinery, moving vehicles, or fall hazards. Computer vision systems can establish virtual safety boundaries around equipment and monitor worker movements to provide audible warnings or automated equipment shutdowns when safety distances are breached. This capability proves particularly valuable in dynamic environments where hazard locations change frequently.

PRIVACY AND WORKER ACCEPTANCE: Implementing computer vision systems requires careful consideration of worker privacy rights and GDPR compliance. Successful deployments involve transparent communication about system capabilities, clear policies on data usage and retention, and worker consultation processes that address concerns whilst emphasising safety benefits. Anonymous detection systems that identify behaviours without recording personal identities often provide optimal balance between safety monitoring and privacy protection.

Ergonomic posture analysis and manual handling monitoring capabilities enable AI to assess worker movements and identify potentially harmful postures or techniques. These systems can provide real-time feedback to workers about lifting technique whilst generating data for targeted training interventions and ergonomic improvement programmes.

Autonomous Systems Removing Humans from Hazardous Tasks

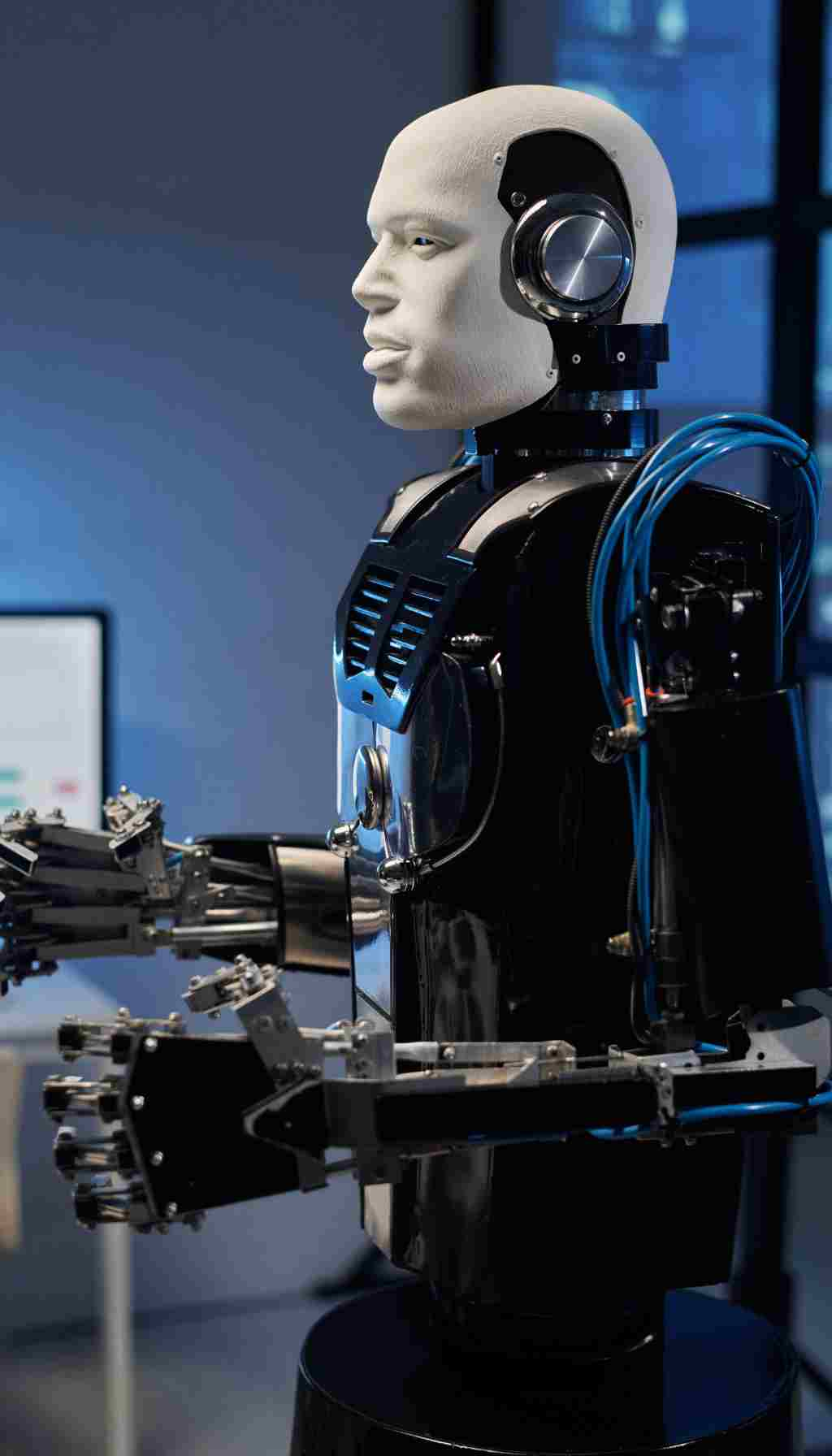

Robotics applications in workplace safety focus primarily on removing human workers from dangerous environments and tasks, eliminating exposure risks entirely rather than simply managing them. Autonomous systems excel in environments that pose significant risks to human health, including explosive atmospheres, toxic material handling, extreme temperature conditions, and radiation exposure scenarios.

Autonomous inspection drones provide cost-effective solutions for working at height inspections, confined space assessments, and infrastructure monitoring that would traditionally require workers to enter hazardous locations. These systems can conduct detailed visual inspections, thermal imaging surveys, and gas detection monitoring whilst keeping human operators safely on the ground or outside dangerous areas.

Automated materials handling systems in warehouses and manufacturing facilities eliminate manual handling risks whilst improving consistency and efficiency. Robotic systems can operate continuously without fatigue, maintaining precise movement patterns that reduce both injury risks and product damage. Integration with inventory management systems enables autonomous systems to optimise workflows for both safety and productivity objectives.

Collaborative Robotics and Human-Machine Integration

Collaborative robots (cobots) represent an emerging category designed to work safely alongside human workers rather than replacing them entirely. These systems incorporate advanced sensors and safety protocols that enable close human-robot collaboration whilst maintaining safety through automatic shutdowns, force limiting, and collision avoidance capabilities.

Benefits of autonomous systems include complete elimination of human exposure to specific hazards, improved consistency in hazardous task execution, and 24/7 operational capabilities that don’t depend on human availability. However, robotics implementation introduces new safety considerations including maintenance requirements, cybersecurity vulnerabilities, and the need for robust fail-safe systems.

Wearable Technology and IoT Sensors

Smart personal protective equipment with embedded sensors transforms traditional safety gear into intelligent monitoring systems that provide real-time data about worker conditions and environmental exposures. These technologies enable continuous assessment of worker safety status whilst maintaining the protective functions that PPE traditionally provides.

Real-time worker location tracking serves multiple safety functions, from lone worker protection systems that trigger alerts when workers fail to check in regularly, to evacuation management systems that account for all personnel during emergency situations. GPS and beacon-based systems can establish virtual safety boundaries and provide automatic alerts when workers enter restricted or hazardous areas.

Environmental monitoring capabilities enable wearable sensors to detect gas concentrations, temperature extremes, noise levels, and other environmental hazards in real-time. Individual exposure monitoring provides personalised data about cumulative exposures that inform both immediate safety decisions and long-term health protection strategies.

QUESTIONS TO ASK WHEN EVALUATING AI SAFETY SOLUTIONS: What specific safety problems will this technology solve? How does the system handle false positives and false negatives? What happens when technology fails or malfunctions? How will workers be trained and consulted about implementation? What data is collected, who has access to it, and how is privacy protected? How does the system integrate with existing safety management processes?

Fatigue and stress indicators provide early warning systems for conditions that increase accident risks, whilst fall detection and emergency response triggering capabilities ensure rapid assistance when incidents occur. Data integration with central safety management systems enables comprehensive analysis of individual and organisational safety performance trends.

Natural Language Processing Intelligent Incident Analysis

Natural Language Processing (NLP) technologies enable AI systems to analyse unstructured text data from incident reports, safety observations, and worker feedback to extract patterns and insights that traditional analysis methods cannot identify efficiently. These capabilities transform vast quantities of written safety data into actionable intelligence for improving safety management systems.

Automated root cause analysis suggestions emerge from AI examination of incident descriptions, witness statements, and investigation reports to identify common factors across multiple incidents. NLP systems can correlate language patterns with incident outcomes to suggest investigation focuses and potential causal factors that human reviewers might overlook.

Safety chatbots provide instant access to safety policies, procedures, and guidance through natural language queries that workers can make in their own words. These systems can handle multiple languages simultaneously, making safety information accessible to diverse workforces whilst reducing the burden on safety professionals for routine policy questions.

Digital Twins Virtual Safety Planning

Digital twin technology creates virtual replicas of physical workplaces, processes, and equipment that enable safety professionals to test scenarios, identify hazards, and optimise procedures without exposing workers to actual risks. These virtual environments incorporate real-world data about equipment performance, environmental conditions, and operational parameters to provide realistic simulations for safety planning purposes.

Scenario simulation capabilities enable safety managers to test emergency response procedures, evaluate the effectiveness of proposed safety interventions, and identify potential hazards in planned work activities before they begin. This proactive approach helps prevent incidents by identifying and addressing risks during the planning phase rather than discovering them during actual operations.

Virtual reality training applications utilise digital twin environments to provide immersive safety training experiences that expose workers to realistic hazard scenarios without actual danger. Workers can practice emergency procedures, hazard recognition skills, and proper work techniques in controlled virtual environments that replicate their actual workplaces.

Opportunities for Irish Businesses

Early adoption of AI and robotics in workplace safety provides competitive advantages that extend far beyond immediate safety improvements. Irish businesses implementing these technologies demonstrate innovation leadership that attracts safety-conscious workers whilst differentiating themselves in markets where safety performance increasingly influences customer and partner selection criteria.

Improved safety outcomes and reduced incident rates translate directly into cost savings through lower insurance premiums, reduced workers’ compensation claims, decreased business disruption, and improved productivity from healthier, more confident workforces. Enhanced regulatory compliance capabilities support organisations in meeting ISO 45001 requirements whilst demonstrating systematic approaches to safety management that satisfy HSA expectations.

Integration with safety management systems enables comprehensive approaches that combine human expertise with technological capabilities to achieve safety performance levels that neither approach could accomplish alone. Scalability advantages mean that solutions can grow with organisations, from SME implementations focused on specific high-risk activities to enterprise-wide systems covering multiple sites and diverse operations.

Implementation Considerations

Organisational readiness assessment represents a crucial first step that evaluates technical infrastructure, workforce capabilities, cultural factors, and change management capacity that influence implementation success. Starting with pilot programmes and proof-of-concept projects enables organisations to learn about technology capabilities and limitations whilst building internal expertise gradually.

Integration with existing safety systems requires careful planning to ensure that new technologies enhance rather than disrupt established procedures. Training safety professionals in new technologies involves developing both technical competencies and strategic understanding of how AI capabilities can be applied effectively within existing safety management frameworks.

Change management and worker engagement strategies must address concerns about job displacement, increased surveillance, and changing work practices whilst emphasising benefits for worker safety and job satisfaction. Vendor selection criteria should include factors beyond technical capabilities, such as data security practices, ongoing support quality, and alignment with organisational values and worker rights commitments.

The Role of Human Safety Professionals

AI and robotics represent augmentation tools that enhance human capabilities rather than replacement technologies that eliminate the need for safety professionals. The most effective implementations combine AI’s pattern recognition and data processing capabilities with human judgment, relationship-building skills, and contextual understanding that technology cannot replicate.

New skills requirements include data literacy for interpreting AI-generated insights, technology management capabilities for overseeing automated systems, and strategic thinking about how technological tools can be applied most effectively within broader safety management approaches. However, core safety professional responsibilities including incident investigation, worker consultation, and safety culture development remain fundamentally human activities that benefit from but cannot be replaced by technological tools.

Interpreting AI insights and making final decisions requires human oversight to ensure that technology recommendations align with organisational objectives, regulatory requirements, and worker welfare considerations. Building safety culture remains irreplaceably human work that depends on relationships, trust, communication, and shared values that technology can support but not create.

Integration with Quality Management

The connection between safety culture and quality management becomes increasingly important as organisations implement integrated management systems. The upcoming ISO 9001:2026 standard’s emphasis on quality culture and ethical behaviour aligns naturally with positive safety culture development, creating opportunities for synergistic improvements that benefit both safety and quality performance.

Action tracking and follow-through systems ensure that identified improvements actually get implemented rather than getting lost in competing priorities. This requires project management disciplines applied to safety improvements, with clear timelines, responsible parties, and success metrics for each initiative.

Celebrating safety wins and milestones maintains momentum for culture change whilst reinforcing desired behaviours. Recognition programmes might include safety performance awards, milestone celebrations for injury-free periods, and public acknowledgment of workers who contribute to safety improvements through suggestions or exemplary behaviour.

Looking Ahead Emerging Trends

Generative AI applications for safety procedure writing and training content development represent near-term opportunities that could significantly reduce the administrative burden on safety professionals whilst improving the consistency and accessibility of safety documentation. Advanced robotics with improved dexterity and decision-making capabilities will expand the range of hazardous tasks that can be automated safely.

5G connectivity will enable real-time connected safety systems that integrate wearable devices, environmental sensors, and automated systems into comprehensive safety networks providing instant response capabilities. Quantum computing applications for complex risk modelling remain in early development but could eventually enable safety scenario analysis of unprecedented sophistication and accuracy.

Timeline expectations suggest that current AI and robotics applications will mature and become more accessible within 1-3 years, whilst more advanced capabilities including sophisticated autonomous systems and integrated safety ecosystems will likely require 3-7 years for widespread adoption. Brain-computer interfaces for direct hazard awareness remain experimental but could eventually provide the most immediate possible warning systems for dangerous conditions.

Getting Started Practical Steps for Irish Employers

GETTING STARTED WITH AI IN SAFETY: PRACTICAL ROADMAP

- Assess current state: Evaluate existing safety data, technology infrastructure, and workforce readiness

- Identify priority use cases: Focus on specific safety challenges where AI could provide clear value

- Start small: Implement pilot projects to build experience and demonstrate value

- Engage stakeholders: Involve workers, unions, and management in planning and implementation

- Address privacy concerns: Develop clear data policies and ensure GDPR compliance

- Build partnerships: Work with technology vendors and consultants who understand safety contexts

- Invest in training: Develop internal capabilities for managing and optimising AI systems

- Measure outcomes: Establish metrics for evaluating safety and business benefits

- Scale successful initiatives: Expand proven applications whilst continuing innovation

- Maintain human oversight: Ensure technology augments rather than replaces human judgment

Building internal capabilities involves developing both technical skills for managing AI systems and strategic understanding of how these technologies can be applied most effectively within existing safety management approaches. Pilot projects provide opportunities to learn about technology capabilities whilst demonstrating value to stakeholders who may be initially sceptical about AI applications.

Continuous improvement and adaptation require ongoing evaluation of AI system performance, regular updates to reflect changing workplace conditions, and systematic learning from both successes and failures in technology implementation.

How AcornStar Supports Digital Safety Transformation

Navigating the complex landscape of AI and robotics in workplace safety requires expertise that combines technological understanding with practical knowledge of safety management and Irish regulatory requirements. At AcornStar, we help Irish organisations develop strategic approaches to digital safety transformation that harness technological opportunities whilst addressing implementation challenges and ethical considerations.

Technology Integration and Strategic Planning

Our HSEQ consultancy services include technology readiness assessments that evaluate organisational capabilities for AI and robotics implementation, vendor evaluation support that helps identify solutions aligned with specific safety needs and organisational values, and strategic planning guidance that integrates technological tools with existing safety management systems.

Change management and worker engagement strategies address the human factors that determine implementation success, ensuring that technological advances enhance rather than undermine safety culture and worker relationships. Our approach recognises that successful AI implementation depends as much on people and processes as on technology itself.

Training and Capability Development

Our training content development services help organisations build internal capabilities for managing AI-powered safety systems whilst maintaining focus on human factors that remain central to effective safety management. We provide digital-age safety seminars that explore practical applications, ethical considerations, and implementation strategies for Irish businesses.

Whether you need strategic guidance for AI implementation, support for vendor selection and system integration, or training programmes that build internal capabilities for digital safety management, AcornStar brings practical expertise and proven methodologies to help Irish organisations harness the transformative potential of AI and robotics whilst maintaining focus on worker welfare and safety culture.