7 Workers Injured Daily: Why Winter Safety Planning Can’t Wait

What You Really Need to Know

Why Winter Safety Planning Is Essential for Irish Workplaces

Winter safety planning is essential for protecting workers as colder weather, reduced daylight, and icy conditions increase workplace risks across Ireland. Each winter, slips, trips, cold stress, and vehicle-related incidents rise sharply, turning routine tasks into dangerous activities. With data showing that seven workers are injured every day due to slips, trips, and falls, employers must take proactive steps to manage winter hazards, protect employee wellbeing, and meet their health and safety responsibilities before conditions worsen.

The days are getting shorter, the mornings are darker, and there’s a crisp chill in the air that signals winter’s approach. For many of us, this seasonal change brings cosy evenings and the anticipation of Christmas. But for employers and safety managers across Ireland, winter means something else entirely: a significant increase in workplace hazards that can turn routine tasks into dangerous activities.

From icy car parks that become slip hazards to freezing conditions that affect workers’ concentration and dexterity, winter presents unique challenges that require proactive planning and proper preparation. The question isn’t whether winter will affect your workplace it’s whether you’ll be ready for it.

The Scale of the Problem Why Winter Safety Matters

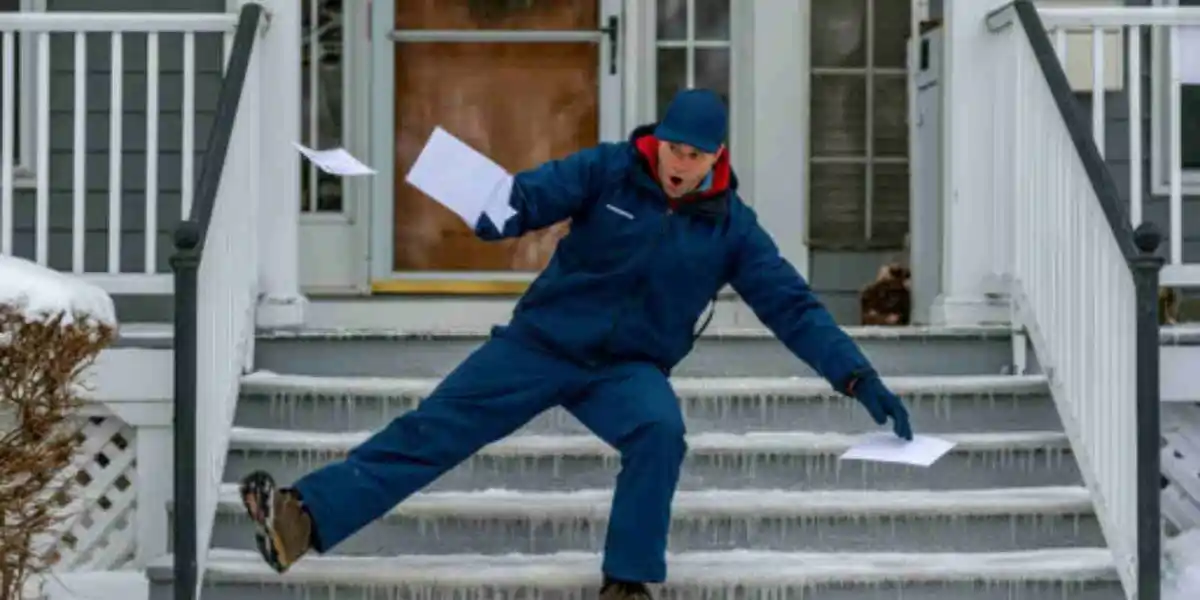

Let’s start with some sobering statistics that highlight just how significant winter workplace safety really is. According to recent data, seven workers are injured every single day in Ireland due to slips, trips, and falls. That’s not just a winter figure that’s year-round. But when winter arrives, these numbers spike dramatically.

KEY STATISTICS: Slips, trips, and falls account for 22% of all workplace accidents in the UK and Ireland making them the single most common cause of workplace injury. Over 10,000 workers suffer serious injuries from slips and trips annually, and remarkably, 95% of major slips result in broken bones.

But it’s not just about workplace accidents. Winter weather affects every aspect of work-related safety. Between 2016 and 2020, there was one road accident every hour in the UK due to snow, ice, floods, fog, and darkness, totalling 44,783 accidents. For businesses with mobile workers or company vehicles, these statistics represent real risks that need managing.

The Health and Safety Authority recognises slips, trips, and falls as a major workplace hazard, particularly during winter months when wet and icy conditions create additional risks that weren’t present during the warmer months.

Why Winter is Particularly Hazardous

Slips, Trips, and Falls

Winter transforms familiar workplace environments into potential hazard zones. Car parks become skating rinks, walkways develop treacherous ice patches, and entrances become slip hazards as people track in water, snow, and salt. HSA guidance on ice and snow emphasises that these conditions require specific prevention strategies beyond normal housekeeping measures.

Reduced Visibility and Shorter Days

With sunrise after 8am and sunset before 5pm during the depths of winter, many workers are commuting and working in darkness. This dramatically increases risks for anyone working outdoors, operating vehicles, or moving between buildings. Poor visibility affects judgement and reaction times, making accidents more likely.

Cold Stress and Physical Impacts

Cold weather doesn’t just make people uncomfortable it creates genuine health and safety risks. Workers exposed to cold conditions experience loss of concentration, increased tiredness, and reduced dexterity. More seriously, cold exposure can lead to muscular injuries, vibration white finger, and in extreme cases, hypothermia and frostbite.

Vehicle-Related Incidents

For businesses with delivery drivers, sales teams, or any mobile workforce, winter weather multiplies the risks associated with work-related driving. Ice, snow, reduced visibility, and longer stopping distances all contribute to increased accident rates.

Legal Requirements and Official Guidance

Understanding your legal obligations around winter workplace safety isn’t just good practice it’s essential for compliance and protecting your business from liability. The good news is that comprehensive guidance is available from both Irish and UK authorities.

The HSA’s winter readiness guidance provides a comprehensive framework for preparing workplaces for seasonal hazards. This isn’t optional reading it represents best practice that could be scrutinised if incidents occur.

Temperature Requirements

UK Government guidance sets clear minimum temperature requirements that also inform Irish best practice: workplaces must maintain at least 16°C for general work, or 13°C where the work involves strenuous physical effort. These aren’t just comfort guidelines they’re safety requirements.

The HSE’s temperature management guidance emphasises that employers must provide reasonable working temperatures and consider the health effects of cold working conditions on their employees.

LEGAL REALITY: If a worker is injured due to preventable winter hazards that you should have reasonably foreseen and managed, your business could face significant liability. Preparation isn’t just about employee welfare it’s about legal protection.

Essential Winter PPE Your Complete Breakdown

Personal Protective Equipment takes on crucial importance during winter months. HSE guidance on PPE at work emphasises that equipment must be suitable for the specific conditions workers will face. Winter working demands specialised consideration.

Layered Clothing Systems

The key to effective cold weather protection is layering. Workers need moisture-wicking base layers to keep skin dry, insulating middle layers to retain body heat, and weather-resistant outer layers to protect against wind, rain, and snow. This system allows for adjustment as activity levels and temperatures change throughout the day.

Hand Protection

Hands lose heat rapidly and are essential for maintaining dexterity and safety. Insulated gloves designed for the specific tasks workers perform are crucial. For construction work, this might mean insulated work gloves with grip enhancement. For outdoor maintenance, waterproof insulated gloves become essential.

Footwear

Perhaps the most critical winter PPE item is appropriate footwear. Anti-slip soles, insulation, and waterproofing are all essential features. Many workplace injuries could be prevented simply by ensuring workers have suitable winter boots rather than relying on regular safety shoes that become hazardous in icy conditions.

High-Visibility Clothing

With reduced daylight hours and poor weather conditions, high-visibility clothing becomes even more critical during winter. Insulated hi-vis jackets that combine warmth with visibility are essential for anyone working near vehicles or in low-light conditions.

Head and Face Protection

Hard hat liners, thermal balaclavas, and insulated caps become necessary for outdoor workers. The head loses heat rapidly, and protecting it helps maintain overall body temperature and concentration levels.

PPE TIP: Don’t forget eye protection. Winter sun reflecting off snow can cause snow blindness, and wind-driven particles become more dangerous when workers’ natural reactions are slowed by cold conditions.

Preventing Slips, Trips, and Falls

Given that slips, trips, and falls represent the most common workplace accidents, and that 95% of major slips result in broken bones, preventing these incidents must be a priority for every business during winter months.

Gritting and Maintenance

Develop a systematic approach to gritting and snow clearance. This means identifying priority routes (main entrances, fire escape routes, frequently used pathways), establishing who’s responsible for treatment, and ensuring adequate supplies of grit or salt are available before they’re needed.

Indoor Measures

Winter hazards don’t stop at the door. Entrances become particularly hazardous as people track in water, snow, and salt. Absorbent mats, regular cleaning schedules, and clear signage about wet floors all become more important during winter months.

Footwear Policies

Consider implementing winter footwear requirements or providing appropriate boots for employees. The cost of providing suitable footwear is minimal compared to the potential costs of workplace injuries and associated disruption.

PRACTICAL MEASURE: Many successful businesses provide boot washing stations at entrances during winter. This simple measure reduces slip hazards while demonstrating commitment to winter safety.

Cold Stress and Health Impacts

Cold stress isn’t just discomfort it’s a genuine occupational health hazard that affects both safety and productivity. Understanding and managing these impacts is crucial for any business with workers exposed to cold conditions.

Physical Effects

Cold temperatures cause muscles, tendons, and ligaments to become stiffer and less flexible. This increases the risk of strains and sprains during manual handling tasks. Workers also experience reduced dexterity, making fine motor tasks more difficult and increasing the risk of accidents.

Cognitive Effects

Cold exposure affects concentration and decision-making ability. Workers may become more prone to errors in judgement, which can have serious safety implications. Reaction times also slow, affecting the ability to respond quickly to hazards.

Serious Health Conditions

Prolonged exposure to cold and vibration can lead to vibration white finger, a serious occupational health condition. In extreme cases, workers can develop hypothermia or frostbite, both of which require immediate medical attention.

RECOGNITION SIGNS: Train supervisors to recognise signs of cold stress including shivering, fatigue, confusion, slurred speech, and loss of coordination. Early intervention can prevent serious health consequences.

Indoor Workplace Considerations

Winter safety isn’t just about outdoor workers. Indoor environments face their own seasonal challenges that require careful management to maintain safe and comfortable working conditions.

Heating and Ventilation

Maintaining appropriate temperatures while ensuring adequate ventilation can be challenging during winter. Poor ventilation can lead to condensation problems, which create slip hazards and can contribute to poor air quality. Regular maintenance of heating systems becomes critical a breakdown during cold weather creates immediate safety and welfare concerns.

Lighting Considerations

With reduced natural daylight, artificial lighting becomes more important. Ensure lighting levels are adequate for safe working, particularly in areas where detailed work is performed or where there are trip hazards.

Emergency Procedures

Winter weather can affect emergency procedures. Escape routes may become hazardous due to ice or snow, and assembly points may need to be reconsidered if they’re exposed to severe weather. Review and update emergency procedures to account for winter conditions.

Practical Tips for Employers

Effective winter safety management requires proactive planning and systematic implementation. Here are practical steps every employer should consider:

Risk Assessments

Update risk assessments to account for winter hazards. This isn’t just about adding a few lines about ice it means systematically reviewing all work activities to identify how winter conditions might affect them. Consider commuting risks, site access issues, and how weather might affect equipment operation.

Training and Awareness

Provide specific training on winter safety. This should cover proper use of winter PPE, recognition of cold stress symptoms, safe walking techniques on icy surfaces, and vehicle safety in winter conditions. Don’t assume people know how to work safely in winter conditions make it explicit.

Facilities and Resources

Provide warm rest areas where workers can recover from cold exposure. Hot drinks, hand warming facilities, and spaces to dry wet clothing all contribute to both safety and morale. Consider providing mobile warming facilities for sites without permanent buildings.

EMPLOYER CHECKLIST:

- Review and update winter risk assessments

- Ensure adequate supplies of grit, salt, and snow clearing equipment

- Check heating systems and lighting before winter arrives

- Provide appropriate winter PPE and training on its use

- Establish clear procedures for severe weather conditions

- Review vehicle maintenance and winter driving policies

- Ensure first aid provisions include cold injury treatment

Employee Responsibilities and Best Practices

While employers have primary responsibility for winter safety, employees also have important roles in maintaining safe working conditions. Understanding these shared responsibilities helps create a culture where everyone contributes to winter safety.

Personal Preparation

Employees should dress appropriately for winter conditions, including proper footwear and layered clothing. They should also take responsibility for their own health, recognising the signs of cold stress and taking appropriate action.

Hazard Reporting

Workers are often the first to notice developing hazards like ice formation or heating problems. Encouraging prompt reporting of winter hazards helps prevent accidents before they occur.

Safe Work Practices

Employees need to adapt their working practices for winter conditions. This might mean allowing extra time for tasks, taking more frequent breaks when working in cold conditions, and being extra vigilant about slip and trip hazards.

TEAM APPROACH: The most successful winter safety programmes involve everyone. When workers understand the risks and their role in managing them, safety outcomes improve significantly.

Preparing for Success

Winter workplace safety doesn’t happen by accident it requires systematic preparation, appropriate resources, and ongoing vigilance. But the investment in proper winter safety measures pays dividends in reduced accidents, improved morale, and business continuity during challenging weather conditions.

The key is to start preparation before winter arrives. Once icy conditions develop or severe weather hits, it’s too late to implement effective safety measures. The businesses that manage winter safety most effectively are those that plan ahead and prepare systematically.

Remember, winter safety isn’t just about compliance with regulations it’s about protecting your most valuable asset: your people. Every slip prevented, every case of cold stress avoided, and every winter-related accident eliminated represents real human benefit as well as business value.

FINAL PREPARATION CHECKLIST:

- Conduct thorough winter risk assessments for all work areas and activities

- Ensure all workers have appropriate winter PPE and understand how to use it

- Establish clear gritting and snow clearance procedures with designated responsibilities

- Check heating systems, lighting, and emergency procedures before winter weather arrives

- Provide training on winter safety, including cold stress recognition and prevention

- Review vehicle safety procedures and ensure winter maintenance is up to date

- Establish communication procedures for severe weather conditions

- Prepare warm rest facilities and ensure first aid provisions include cold injury treatment

- Create systems for ongoing monitoring and review of winter safety measures

Winter will come whether we’re ready or not. The question is whether your business will be prepared to keep everyone safe, productive, and protected throughout the challenging months ahead. With proper planning, appropriate resources, and systematic implementation, winter doesn’t have to mean increased risk it can mean an opportunity to demonstrate your commitment to employee welfare and operational excellence.

Keep your staff up to date with essential food safety practices through our Online Food Safety Courses, or learn how our Consultancy Services can help you build a stronger compliance culture.

Accredited HACCP Certification, A Powerful Marketing Tool

Why Accredited HACCP Certification Is Your Food Business’s Best Marketing Tool HACCP Corrective Actions: The Most Common Compliance Mistake Why HACCP Certification Is No Longer Just About Compliance When most Irish food business operators think about HACCP...

Fire Warden Responsibilities, What They Really Do

Fire Warden Responsibilities, What They Really Do at Work Fire Warden Training Ireland: Duties, Checks & Evacuation What Does a Fire Warden Do in an Emergency? Fire warden responsibilities go far beyond wearing a high-vis vest and standing beside the fire exit. In...

The Growing Importance of Allergen Awareness Training in Ireland

Why Allergen Awareness Training Is Critical for Irish Food Businesses Already good and generating greens leave it unless you’re chasing perfection. The Growing Importance of Allergen Awareness Training in Ireland Food allergies are a major public health concern in...

Fire Safety Legislation Ireland, Compliance Guide

Fire Safety Training Ireland, Is Your Business Compliant? Fire risk assessment Ireland requirements for businesses. Learn how to meet fire safety law. Understanding Your Legal Duties Under Irish Fire Safety Law Fire safety legislation Ireland places clear legal duties...

Manual Handling Training ROI: An Investment, Not an Expense

Why Manual Handling Training Is an Investment, Not an Expense Why Manual Handling Training is an Investment, Not an Expense The True Cost of Workplace Injuries in Ireland Many Irish employers still treat manual handling training as a compliance cost rather than a...

Food Safety in Healthcare Ireland: HACCP Compliance

Food Safety in Healthcare Ireland. Why HACCP Compliance Is Essential Healthcare food safety standards Ireland demand accredited HACCP systems. Learn what regulators now expect. Why Food Safety Risks Are Higher in Healthcare Settings Food safety in healthcare Ireland...

Manual Handling Compliance Ireland: Legal Duties

The “Acornstar Standard”: Why Accredited Training Beats “In-House” Talks What Every Irish Employer Must Know About Manual Handling Compliance Before the HSA Inspector Arrives Manual Handling Training in Ireland Legal Requirements for Employers Manual handling...

Operational Excellence in Ireland: Training & Safety Systems

Operational Excellence The Blueprint for Professional Standards What You Really Need to Know Why Operational Excellence Matters More Than Ever Operational excellence is no longer a competitive advantage it is the minimum standard expected of food, hospitality,...

HSA Manual Handling Statistics Ireland (2025)

HSA Annual Review 2025: Manual Handling Remains the #1 Cause of Workplace Injury Protecting Your Workforce Through Evidence-Based Manual Handling Training The Good News and the Concerning Trend The latest HSA manual handling statistics Ireland reveal that manual...

Manual Handling Training Ireland | Preventing Back Injuries at Work

We Have Your Back: The Science of Injury Prevention Protecting Your Workforce Through Evidence-Based Manual Handling Training Introduction: The Hidden Epidemic Affecting Irish Workplaces Every day across Ireland, thousands of workers lift, carry, push and pull loads...